The Importance of Water Recycling + Reuse in QLD’s Coal Mining Industry

Water is essential for the coal mining industry, especially in Queensland, where mining operations are extensive, and water scarcity is a real challenge. The industry relies on water for various processes, including dust suppression, mining operations, and resource processing. This heavy reliance, combined with other water users, presents both risks and opportunities for local water resources, particularly in areas like the Fitzroy Basin, which can experience prolonged periods of low rainfall. The mining sector has the expertise and capacity to drive sustainable practices, such as water recycling and reuse.

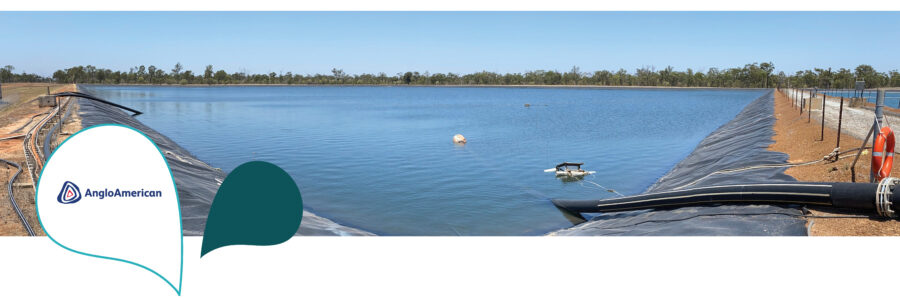

At Anglo American’s steelmaking coal operations across the Fitzroy Basin, we’ve been proactive in implementing water recycling and reuse initiatives to contribute nature-positive outcomes for local water resources. Since 2020, we’ve increased our reuse and recycling from 50% to 65% of total water use. In 2024 alone, this led to a reduction of 1,023 million litres of freshwater withdrawal. A number of benefits for our operations include:

- Reduction in freshwater consumption: By recycling and reusing water, we significantly reduce our reliance on external freshwater sources. This not only eases pressure on local water resources but also lowers our usage costs and allows us to return surplus water to the market for other beneficial uses.

- Future cost savings: Implementing water treatment technologies and increasing reuse opportunities has helped us reduce stored mine water. This is crucial because this stored water typically need to be treated at mine closure, which can be complex and costly.

- Enhanced resource efficiency: Maximising the use of all available water resources has improved our overall operational water efficiency across our Central Queensland operations. Our sustainable water management practices serve as examples for other parts of our business and potentially externally, showcasing reuse and recycling options, learnings, and improvements.

- Environmental Benefits: Effective water management strategies reduce our ecological footprint and promote sustainable mining practices. By implementing comprehensive water recycling systems, we significantly mitigate risks associated with water scarcity, pollution, and habitat destruction.

Several innovative technologies and case studies highlight the potential of water recycling and reuse in the mining industry:

- Reverse Osmosis (RO): Our RO plant at Capcoal employs a widely used technology that effectively removes contaminants from saline mine-affected water, making it suitable for reuse in mining operations.

- Closed-loop systems: These systems recycle water internally, minimising discharge and environmental impact. Continuous monitoring and optimisation using advanced sensors and data analytics enhance treatment processes, ensuring optimal efficiency and minimal waste.

- Collaborative partnerships: Engaging with regional communities, industry and regulators for shared water resource management enables strong water stewardship and provides opportunities to improve and grow sustainable practices. Collaborative platforms, such as that offered by the FPRH, lead to more sustainable water management practices and better community outcomes.

Water recycling and reuse are critical for the coal mining industry in Queensland to reduce the impact on regional water resources. These practices offer numerous benefits, including reduced freshwater consumption, cost savings, enhanced resource efficiency, and environmental sustainability. By adopting innovative technologies and engaging in collaborative partnerships, we ensure water stewardship is part of how we operate across all our sites and help contribute to a more sustainable future. Embracing sustainable water management practices will be essential for ensuring the long-term viability of our mining operations and the preservation of local water resources.